Physical modelling

We have the most modern and extensive suite of physical modelling facilities available anywhere in the world.

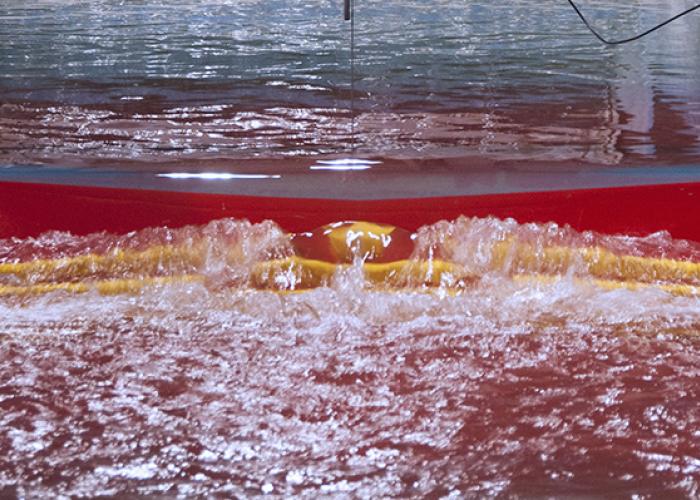

Our state of the art physical modelling facilities are housed in three purpose built halls, extending to around 14,400 m2, and include:

- Wave basins, both separate and linked units capable of extension to 2,400 m²

- Wave-current or current only basin with uni- or bidirectional current discharges

- Fast Flow Facility, a unique wavecurrent-sediment flume

- Wave flumes equipped with wave absorbing paddles to compensate for wave reflections

- Volumetric flow flume with certified volumetric measurement capability

- Hydraulic structure and river floodplain modelling area

- Specialist facilities for tsunami simulation, flood protection product testing and aircraft ditching studies.

- Erosion test facilities for measuring erosion rates in sediment core samples.

Find out more about how we run physical modelling tests

Explore our physical modelling facilities

Take a virtual tour

Want to know more?

Joe Mitchell

Laboratory Manager

+44 (0)1491 822899