Fast Flow Facility

One of the world’s largest marine test facilities, the Fast Flow Facility delivers a world-leading capability in wave-current-sediment-structure modelling.

The Fast Flow Facility is one of the largest marine test facilities in the world. The unique dual-channel, race track shaped flume offers waves, fast tidal currents and sediment capabilities. Understanding the complex way waves, currents and sediments interact with structures is vital to the successful delivery of projects in the marine environment, and the Fast Flow Facility allows us to do this at a larger scale and in greater detail than ever before. We can study sediment transport, scour and morphology for a wide range of subsea, coastal, estuarine and fluvial engineering projects, as well as the combined impact of waves and currents on structures in a completely controllable, measureable environment.

Fast Flow Facility snapshots

The Fast Flow Facility is one of the world’s largest marine test facilities.

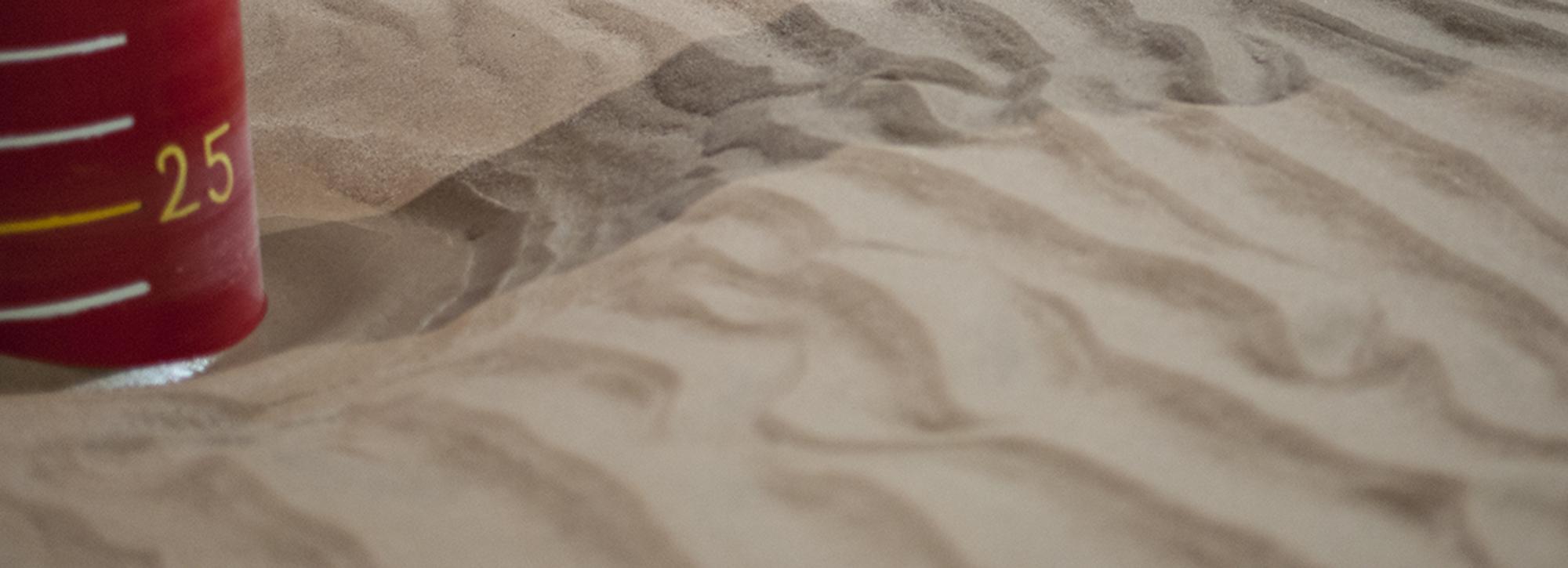

Predicting the movement of unexploded ordnance in the North Sea.

We use the Fast Flow Facility to assess scour protection around pipelines and cables.

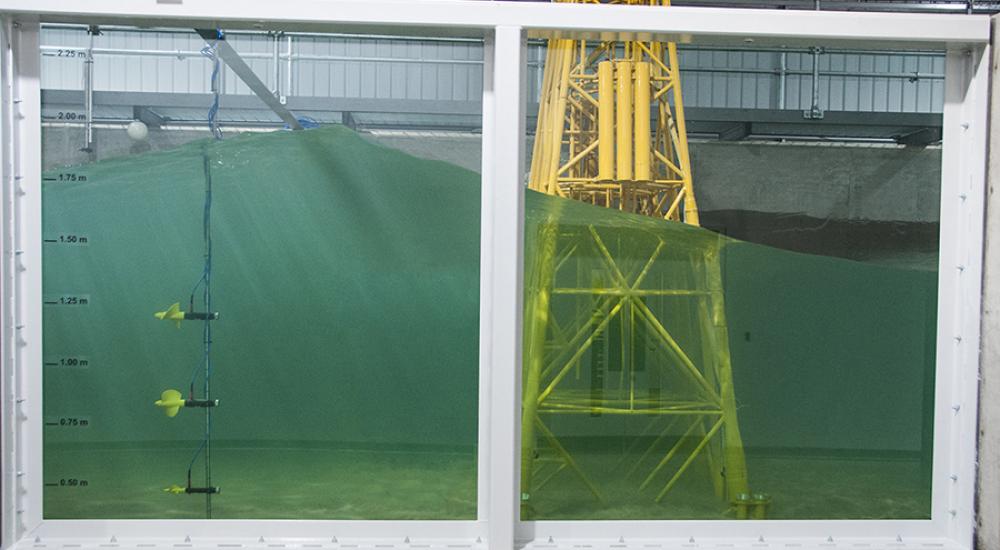

Offshore jacket testing in the Fast Flow Facility

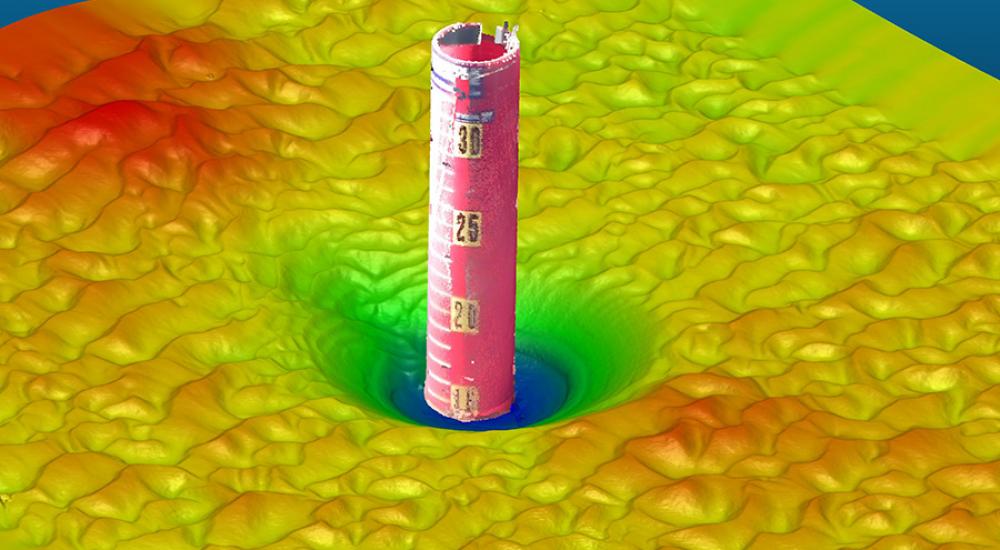

We can use the Fast Flow Facility to assess scour around the base of wind turbines.

The size of the Fast Flow Facility allows us to model at larger scales.

Testing of an offshore substation jacket in the Fast Flow Facility for the University of Rostock at a scale of 1:60.

Testing the performance of a frond mat scour protection system to protect the jacket piles for EA ONE.

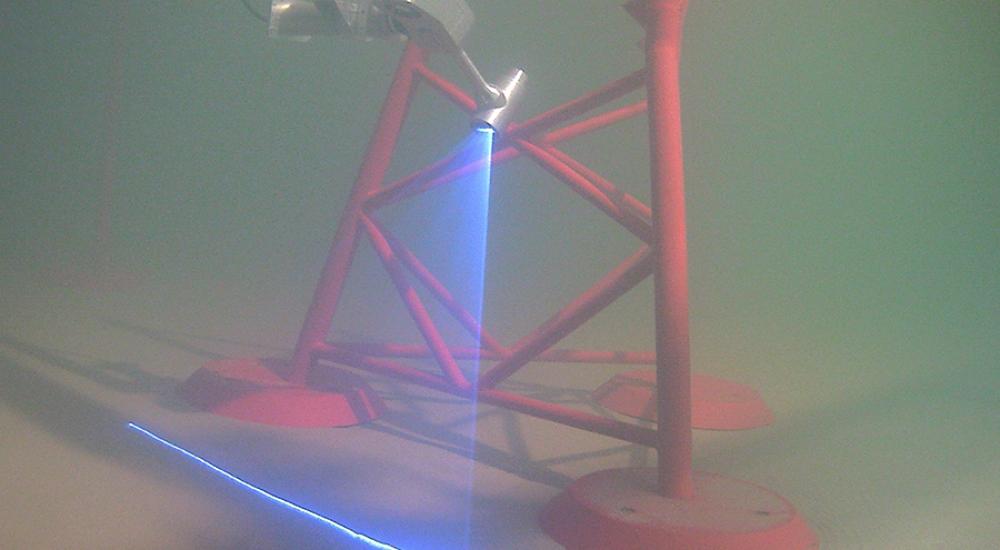

Assessing the use of tyre-filled nets as a remedial measure for seabed scour at offshore foundations.

We use 3D laser scanners to accurately measure scour formation.

Our underwater cameras and laser scanners in operation.

Reducing scale effects, minimising uncertainty

The 75 m long Fast Flow Facility holds 1 million litres of water and is able to generate waves of up to 1 m high and flows of over 2 m/s. The size of the facility allows us to model complex structures and arrays, crucially, without compromising on scale. The main working channel has a 57 m long test section, providing the space to look at array effects, long wakes behind structures and the relative placement of structures and devices. The deep pit area allows us to push the boundaries in scour and erosion testing, offering unique insight and innovative solutions. By operating at a large scale, model effects are reduced, increasing certainty for our clients in our results. This allows our clients to minimise design risks during the early stages of their projects.

In the marine renewable energy sector, developments in exposed marine environments are high risk: fast currents, deep water and energetic waves present significant technical challenges. The Fast Flow Facility is able to model large structures and arrays, without compromising on scale, meaning that we can help our clients to plan, install and maintain their assets in the most efficient way possible.

The world-leading Fast Flow Facility is also home to world’s most accurate tsunami generator. Previously, study of tsunamis has been composed of two phases: single, large waves are used to measure the initial impact forces on buildings and other structures, while pumped, recirculating flow is used to measure the forces and cumulative damage caused by the overtopping of long period waves. The only generator of its kind in the world, the HR Wallingford 3rd generation Tsunami Simulator is able to combine these effects – providing initial impact forces as well as overtopping. The simulator is able to reproduce real-world tsunami traces (e.g. the well-known “Mercator” trace from the Indian Ocean tsunami in 2004) to allow in depth study of real-world events.

The Fast Flow Facility has a dedicated project team, with unrivaled knowledge and experience, that look forward to answering your enquiries and taking on your challenging projects.

- Main working channel size of 57 m by 4 m

- Secondary working channel of 50 m by 2.6 m

- Water depth range 0.8 m to 2 m

- 1 m deep (16 m3) test pit for sediment or subsurface studies

- Hinge flap type multi-element wavemaker with active wave absorption

- Significant wave heights up to 0.5 m and maximum wave height 1.0 m

- Reversible pumps to simulate unidirectional or tidal currents, with discharge capacity to generate flows of over 1.5 m/s

- State of the art monitoring and data collection instrumentation

- Fully customisable bathymetry

- Three large viewing windows, each 4m wide and full flume height (2.5 m)

- Dedicated fast flow facility testing team with world-class technical knowledge/ experience

- Versatile facility for varied science and engineering hydraulic and sediment research

- Wave-current-sediment-structure studies

- Foundation stability and scour protection

- Seabed-structure interaction

- Wave-current interaction

- Sediment transport under flows, waves and currents

- Morphology: rivers, coasts and estuaries

- Breakwaters - stability, overtopping, wave forces and pressures

- Tsunami: the world’s most accurate tsunami generator

- Instrumentation proving

- Loading on structures

- Floating structures

- Sea-keeping tests

- Drag experiments

- Hydrometry

Using the Fast Flow Facility to assess scour protection for offshore structures

What our partners say about the Fast Flow Facility

The ability to have novel designs tested by physical modelling is crucial for development of our foundations. We can observe how the seabed responds to the foundation in the extreme conditions found in the North Sea. We have found the new Fast Flow Facility at HR Wallingford tailor made for this purpose.

Our research using the 3rd generation Tsunami Simulator in the world-leading Fast Flow Facility has allowed us to create the longest and most accurate tsunami ever seen in the laboratory, furthering our understanding of both tsunami as a phenomena and the associated, complex scour processes. The results of this work will make a real-world difference, leading to better coastal protection and reduced loss of life in future disasters.

The ability of the Fast Flow Facility to replicate the scour, self-burial and mobilisation processes involved with UXO prediction at full-scale gives us great confidence in the results.

For scour tests, we provided two models of steel jacket foundations at a scale of 1:60. The data we have been gathering in HR Wallingford’s world-leading facilities is deepening our understanding of the effects of scour on offshore substation jackets in the German sector of the North Sea where substantial offshore wind development is both ongoing and being planned.

HR Wallingford is a world-leading organisation in physical modelling, scour evaluation and scour protection design.

Want to know more?