Cable congestion

We’ve been helping Ørsted to build stable cable crossings on an increasingly congested seabed.

The UK has one of the largest offshore windfarm estates in the world. Some 7000 turbines across 32 sites contribute up to 30 per cent of the power delivered to the National Grid at any one time. Each new windfarm must be ‘plugged in’ onshore using buried sub-sea cables. The most recently constructed Round 3 windfarms are experiencing a new phenomenon - a congested seabed with a complex network of existing cables and pipelines that new cables must cross in order to make it to land.

We helped Danish renewable power giant Ørsted to plug in their new Walney Extension windfarm. The four existing windfarms in Morecambe Bay along with gas pipelines and telecom cables meant that there were eight obstacles in the way. To get over these obstacles, they needed to bring the buried cable up out of the seabed, over the existing asset, and then rebury it. The exposed cabling must then be secured, usually with a cover of rock - a rock berm.

Rock berms can sometimes be problematic, causing large holes to be scoured in to the seabed, sometimes extending hundreds of metres from the structure. This scour can expose the existing assets. This can result in very expensive repair bills, so it has become more and more important to get the design right before installation.

HR Wallingford has provided expert services to over 90 per cent of the UK’s offshore windfarms. When Ørsted wanted to apply lessons learnt from existing cable crossings, and apply them to the eight crossings to be constructed for Walney Extension, they partnered with us for advice.

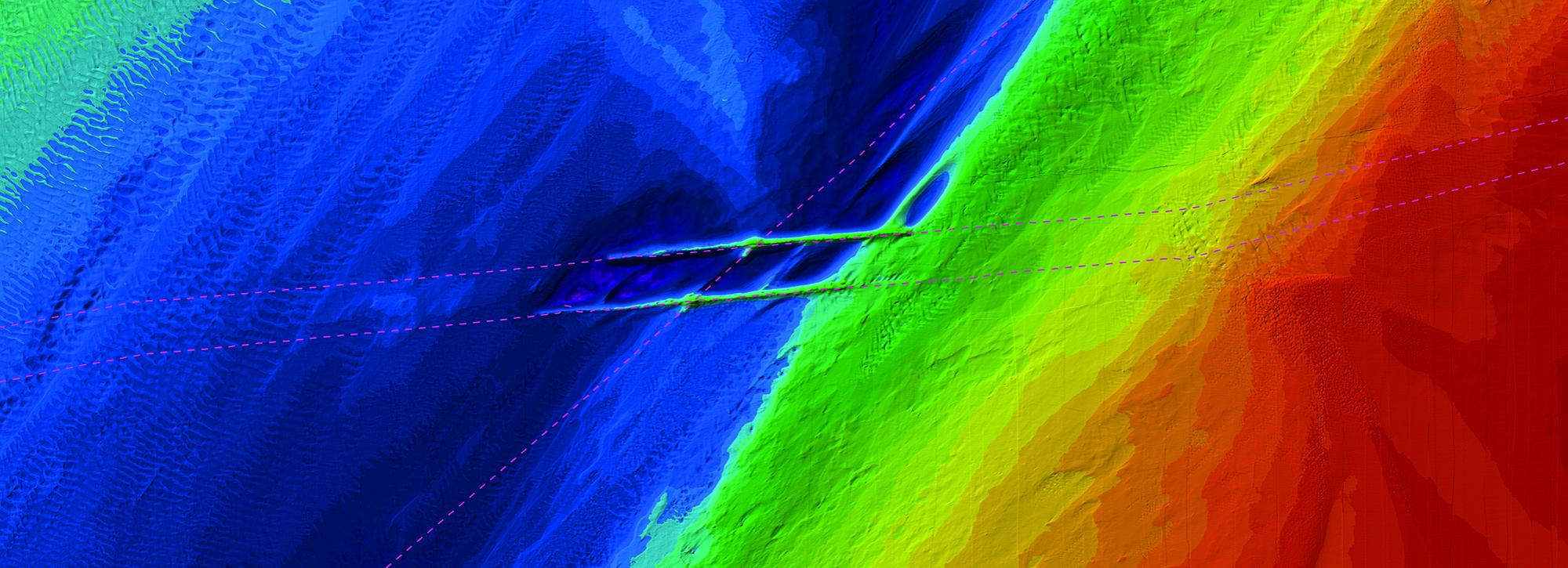

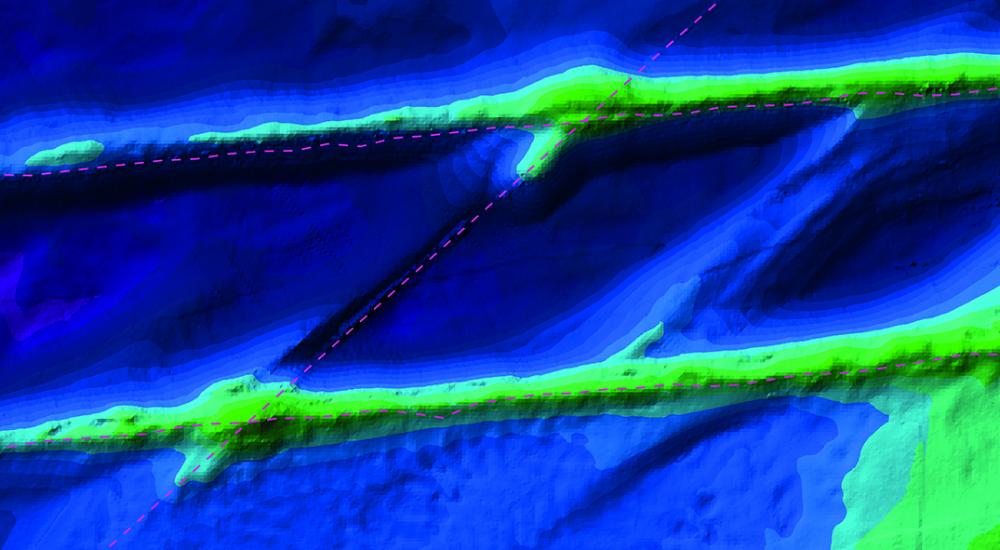

The image, below, shows rock berms on two cables installed near to each other. The conditions including water depth, sediment type, rock size and berm dimensions are largely the same at the two berm sites. The main difference is the orientation of the rock berm to the fast tidal flows of Morecambe Bay, which boasts one of the largest tidal ranges in the world. The direction of the flow can be seen in the scour pattern that developed for the more southern of the two berms. Cross-referencing this direction with the orientation of the more northerly berm, it is apparent that this berm causes less of an obstacle to the tidal flows, and scour is minimised to virtually nothing.

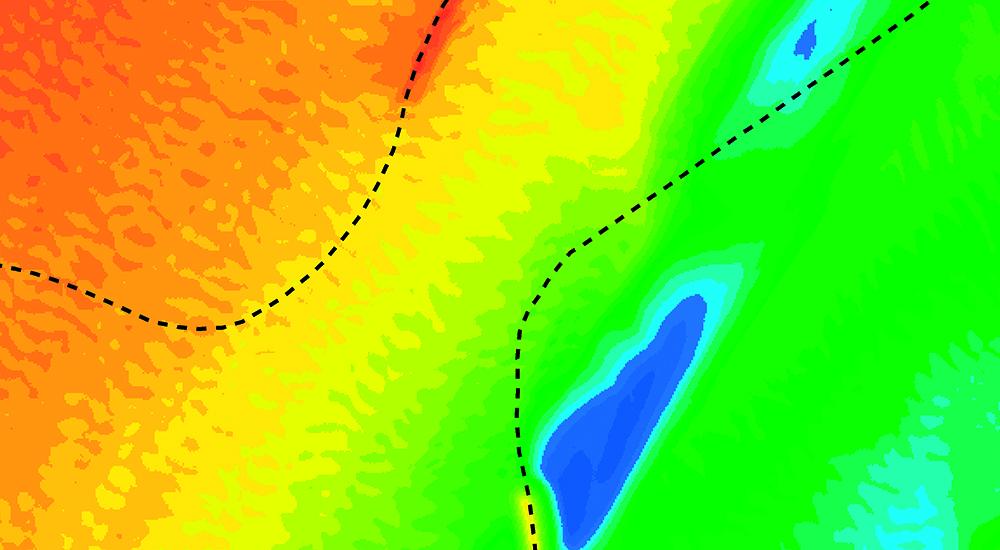

Scour can expose pipelines and cables, as this close-up illustrates, and result in costly repair bills.

The orientation of the southern rock berm to the fast tidal flows of Morecambe Bay resulted in significant scouring of the seabed. The northern berm causes less of an obstacle and scour is minimised.

We captured this simple but powerful field observation and combined it with previous knowledge to produce a set of engineering guidelines. These guidelines were also informed by physical modelling tests in our Fast Flow Facility; these were jointly funded by Ørsted and HR Wallingford’s research and development programme. The tests further demonstrated how important is it to streamline the berm profiles to minimise the turbulence generated as the tidal flows encounter the obstacle.

Ørsted used these guidelines when designing their eight cable crossing rock berms for Walney. The favourable orientation of rock berm axis to the tidal flow was deemed so important, that the final cable routes were updated to optimise the angles - no small undertaking on such a huge project. The rock berms were installed in late 2017, and HR Wallingford’s expertise was once again called upon to assess the as-built footprints relative to the design. No scour was observed in the post-installation surveys, indicating that the design guidelines are very effective at minimising scour risk.

The work behind these guidelines is the focus of two joint publications by Ørsted and HR Wallingford.

Want to know more?