Tailings dam failures - can we minimise the risks?

Following the catastrophic failure of the Brumadinho tailings dam in Brazil, Craig Goff considers the risks associated with these types of dam.

The terrible human tragedy at a mining dam in Brazil last week has once again raised awareness of the risks posed by dams located upstream of population centres.

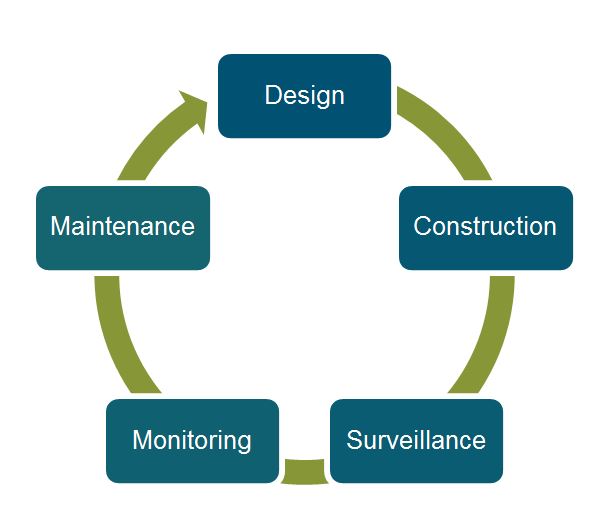

Dam failures of any type are fortunately rare, but, when they do occur these are incidents that can have severe consequences with mass loss of life and environmental and financial consequences in the billions of dollars. It is therefore crucial that we minimise the chance of a dam failure by rigorously improving safety at each point of the dam lifecycle.

What causes dams to fail?

There are typically two main ways an earthen embankment dam can fail – either by internal erosion or external erosion. In the case of internal erosion, water penetrates the outer waterproof barrier and erodes material away from within the body of the dam, creating a hole that gets bigger and bigger until the embankment can no longer hold back the force of the water in the reservoir. With external erosion, water from large waves or uncontrolled rising water levels flows over the top of the dam and erodes material away from the outside, leading to the same effect.

The earliest large dams date back to about 3000BC. It is telling that the earliest known example (Saad-el Kafara, Egypt) is thought to have failed during construction, with the devastation caused dissuading ancient civilizations from similar large dam construction for a period of some 800 years. However it is only in the last two hundred years that the engineering science behind dam engineering has developed rapidly, allowing us to build dams that are, by and large, very safe and very large (more than 300m high).

Are tailings dams more likely to fail?

Earthen embankments are used as part of mining operations to store the mine by-products (tailings) that often comprise toxic waste. These structures are known as tailings dams or tailings storage facilities. The failure rate of tailings dams worldwide over the past 100 years has been estimated to be 1.2%1, which is more than two orders of magnitude higher than the failure rate of conventional water retention dams at 0.01%2. There are many reasons why tailings dams are ‘riskier’ structures than water-retaining dams, and many responsible mining companies are making great efforts to improve and enhance each aspect of the lifecycle of these structures. However, there are also clearly issues around the economics of mining that may lead to sub-standard aspects throughout each stage in the tailings dam lifecycle.

Tailings dams differ from water dams in several ways:

- they are often raised repeatedly throughout their lives;

- they store a mixture of water and (sometimes toxic) minerals in their reservoirs; and

- when the reservoir is ‘full’ or mining operations cease they are left in place, rather than removed.

This means that the risk to a downstream population remains for many years even if the dam has been properly ‘closed’. In many countries mining operations are carried out by “junior miners”. These are a mining companies with only a limited amount of capital. If they do not “strike it rich” before their debt is due, they may have no choice but to file for bankruptcy and abandon their mining operations leaving a legacy of orphaned tailings dams in their wake. These issues, combined with the often remote, developing country locations of tailings dams make long term monitoring of the safety of these structures extremely challenging.

How can we minimise the risks?

HR Wallingford is leading a consortium to use space-data to develop a system called DAMSAT that can help improve the monitoring of tailings dams. Aimed primarily at regulators responsible for monitoring many tailings sites over a large area, this system will help improve transparency within the sector. It could also provide vital extra time to deal with a potentially risky situation.

Funded by the UK Space Agency’s International Partnership Programme, we are using meteorological forecasts coupled with hydrological models to try to predict the impacts of rainfall on the reservoirs and the embankment structures. By exploiting Global Navigation Satellite System (GNSS) data with base stations, we can gather accurate movement data for key points on a structure, and by using Interferometric Synthetic-Aperture Radar (InSAR) data we can monitor movement over wide areas to give warning of landslides or slips. Optical satellite data sets will allow us to monitor indicators of pollutants that may leak from a tailings dam. All of this data will be gathered and analysed in a secure cloud-based system provided by project partner Siemens, and pre-modelled dam-breach flood scenario data can be stored here for use by emergency planners to call upon in the event of an emergency.

The DAMSAT project runs from April 2018 to October 2020 and the team is making good progress. Work is funded by the UK Space Agency’s International Partnership Programme, and the international collaboration includes Telespazio VEGA, Siemens Corporate Technology, Satellite Application Catapult, Oxford Policy Management, and the Smith School of Enterprise and the Environment at Oxford University. Partners in Peru are Ciemam SAC, the National Foundation for Hydraulic Engineering (Peru), and the National University of Cajamarca: School of Hydraulic Engineering and Faculty of Engineering.

The UK Space Agency’s International Partnership Programme (IPP ) is a five-year, £152 million programme designed to partner UK space expertise with overseas governments and organisations. It is funded from the Department of Business, Energy and Industrial Strategy’s Global Challenges Research Fund (GCRF).

Want to know more?

Further information