Fatigue research to optimise offshore wind design

Offshore wind turbines, a vital part of global net zero ambitions, must be able to withstand continuous exposure to wind and wave forces throughout their 20–25-year design life. Our research project aims to accurately assess the fatigue life of the substructures, which will help optimise design and potentially lead to costs savings.

The offshore wind sector operates in an environment which is harsh and complex, requiring turbines to withstand forces from wind and waves, and potentially currents too. Over time, damage accumulates from the wave loads that repeatedly hit the turbine, and this fatigue can potentially lead to mechanical failure of steel components.

Accurate estimates of fatigue life are not only vital to ensure safety but could also potentially reduce material costs. Such savings are crucial for the offshore wind sector where margins are narrower than for more established energy industries.

To make certain that fatigue analysis ensures the safety of steel structures, design codes and standards have been adapted over time. Methods of fatigue analysis currently used in design consider an accumulation of damage, based on the stress range and number of cycles.

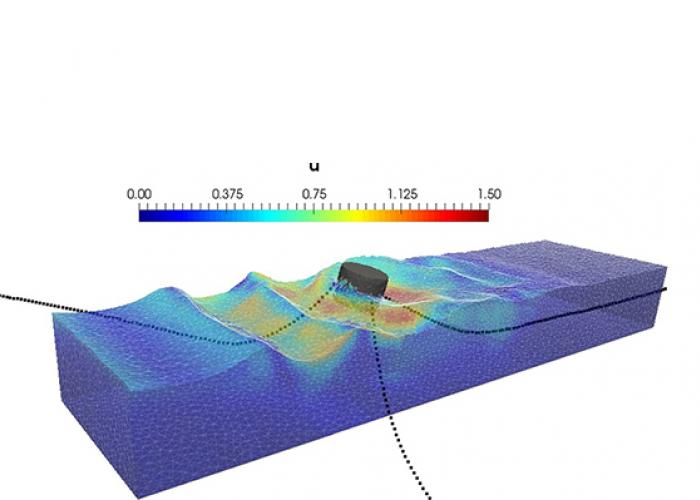

However, there is considerable uncertainty in the actual stress magnitude and number of cycles that a structural component may experience over its design life. We are therefore developing hi-fidelity techniques that can reduce the uncertainty related to the estimated wave loads that are used in the fatigue analysis of offshore fixed and floating wind structures.

Our approach

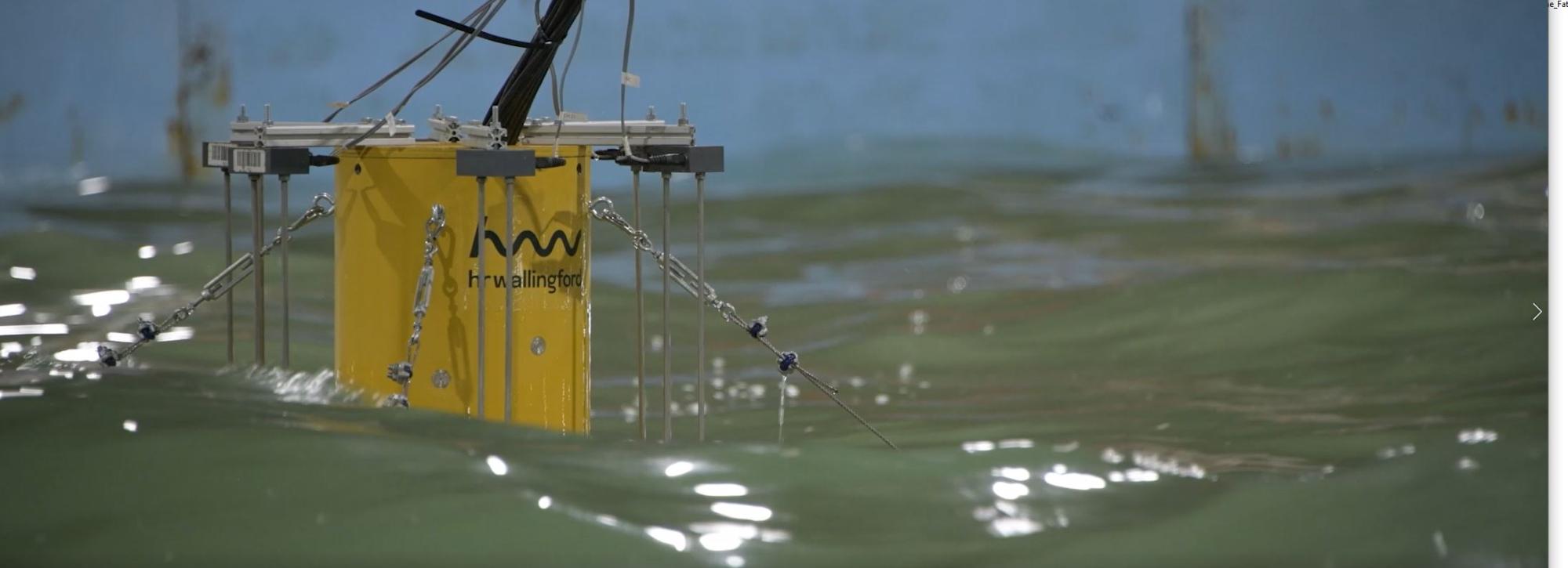

In our modelling hall, we have run physical tests that captured the wave loads hitting a 1:40 scale model of an International Energy Agency reference monopile for a 15 MW offshore turbine. This data will serve as a benchmark for validating and calibrating our computational fluid dynamics (CFD) model, ensuring confidence in the simulated wave conditions and ultimately enabling a reliable estimation of the structure's fatigue life.

We are using high-performance computing to analyse the long time series wave data that we have captured. After calculating the wave loads, we will conduct finite element analysis – the standard method to calculate the corresponding stress within the structure.

We will these use this data to calculate the accumulation of the damage within the structure, which then can be used to assess the fatigue life of any offshore structure, be that floating or fixed.

Ideally placed

We are in a unique position to deliver this research, which combines our capability and expertise on:

- Numerical CFD modelling of fixed and floating structures in random seas

- Physical modelling of nearshore and offshore structures

- Probabilistic design and statistical analysis of storm sequencing over the design life of an asset

Want to know more?

Contact our project lead